Working on Biosphere 2 gave me insight into what I really considered environmentally

appropriate building. I came back to Wisconsin to explore a more accessible form

of "ecologically active" or "living" architecture than was available in the Biosphere

project.

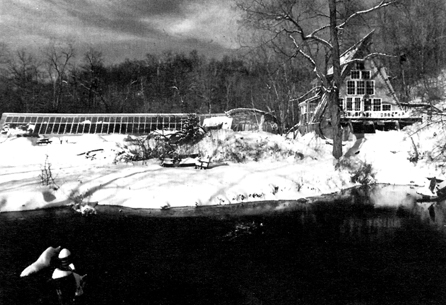

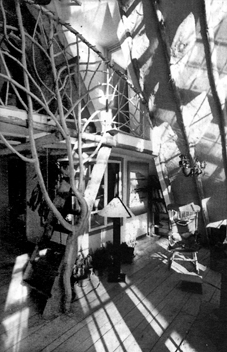

Solar greenhouses and agrarian architecture are natural points of departure as buildings

welcoming life other than human. By inviting life, particularly plants and soil bacteria,

into our buildings, we can clean and recycle our air, water, and biological wastes onsite while producing food, solar heat and light. Extrapolate this integration

of ecology with architecture from rural, to suburban, and even urban buildings, and

- I believe - we could see the dominant predacious or parasitic forms of human ecology evolve into more photosynthetic and ecologically diverse cultures.

My point of departure is at America's grass roots: the family farm, a culture still

alive and growing in Wisconsin. I see the solar greenhouse as the "new barn" at the

heart of diverse organic farms growing crops year round. I see "sustainable" architecture in the old farm buildings throughout Wisconsin, built from locally-abundant materials.

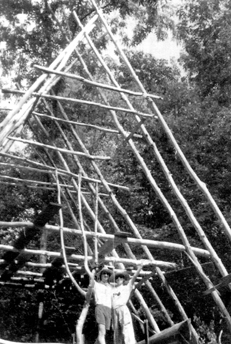

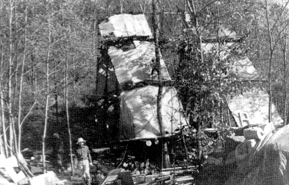

This is the work I'm building on. As with these buildings, my palette is locally-abundant

rocks, dirt, sand, water and fast growing plants, primarily grasses and trees: hence poplar-pole frames and straw-bale construction...

|

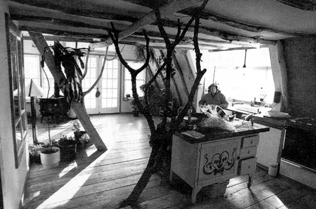

Roald Gundersen pointing out details of interior construction.

|